Saturday, December 3, 2016

9. Identify hybrid vehicle auxiliary (12v) battery service, repair, and test procedures. P-3.

In auto 170 we learned about the dangers of hybrid vehicles. Hybrid vehicles run extremely high voltages and currents so much so it could easily kill a person. So we learned just exactly the proper procedures to take when handling hybrid cars. Hybrid cars use orange cables to indicate the high voltage circuits and special care is to be used with them.

8. Identify electronic modules, security systems, radios, and other accessories that require reinitialization or code entry after reconnecting vehicle battery. P-1.

In auto 170 we learned that disconnecting the battery can cause the clock or radio stations to be reset. Using service info on AllData to do the proper manufacture protocols to store the info. Some vehicles require a special tool to keep a voltage going to the radio clock and such. Newer systems allow info to be stored and set using a obd2 scan tool.

7. Identify high-voltage circuits of electric or hybrid electric vehicle and related safety precautions. P-3.

In auto 170 we learned about the dangers of hybrid vehicles. Hybrid vehicles run extremely high voltages and currents so much so it could easily kill a person. So we learned just exactly the proper procedures to take when handling hybrid cars. Hybrid cars use orange cables to indicate the high voltage circuits and special care is to be used with them.

6. Jump-start vehicle using jumper cables and a booster battery or an auxiliary power supply. P-1.

Little known to most people jump starting someone's car can be very dangerous and in some cases can damage your own vehicle. Its important to know the proper way of connecting jumper cables. First connect the positive to the good battery, then the negative to the good battery. Next connect the other positive to the bad battery, then connect the other negative to a ground source at least 18 inches away from the battery.

5. Perform slow/fast battery charge according to manufacturer’s recommendation.P-1.

In auto 170 we set up battery chargers on the vehicles in the lab on a slow stable charge from manufacture specifications. When set on fast charge its very important to monitor the battery's temperature to avoid explosions or damage to the battery. Always connect the connectors before turning on the machine to avoid sparks and explosions.

4. Inspect and clean battery; fill battery cells; check battery cables, connectors, clamps, and hold-downs. P-1.

3. Maintain or restore electronic memory functions. P-1.

In auto 170 we learned that disconnecting the battery can cause the clock or radio stations to be reset. Using service info on AllData to do the proper manufacture protocols to store the info. Some vehicles require a special tool to keep a voltage going to the radio clock and such.

2. Confirm proper battery capacity for vehicle application; perform battery capacity test; determine necessary action. P-1.

Using service info from all data or prodemand we practiced looking up and determining the proper battery for the vehicles we worked on. Then using tools such as the multimeter and load tester tested the battery to check the voltage. After collecting the necessary info we determined if the battery could be charged or if it needed replacing.

1. Perform battery state-of-charge test; determine necessary action. P-1.

Using a multimeter to perform a state-of-charge test in auto 170 we checked to see if the battery was good or dieing. After disconnecting the drip chargers and dissipating the surface charge we checked to see if the voltage of the battery is proper. If the battery test shows a low reading the battery should be replace because its capacity has deteriorated.

13. Perform solder repair of electrical wiring. P-1.

In auto 170 we practiced soldering by soldering three different joint types. T joint, hook joint, and twist joint shown above are three great ways to get a good mechanical connection to have a good soldered joint. Soldering is a skill that a auto technician must be able to do to preform any electrical work.

12. Repair wiring harness. P-1.

In auto 170 we learned how to repair wiring harnesses. In some cases the connectors break or corrode and need to be replaced, above on the left shows me removing the connector end. Soldering is a valuable skill needed to repair broken wires or replacing corroded or frayed wiring.

11. Replace electrical connectors and terminal ends. P-1.

In auto 170 we learned how to remove connector ends properly. Though there are many different kinds of connectors the way to disassemble them is generally the same. Above shows the way to disassemble a connector with the use of the special appropriate terminal removal tools.

10. Inspect and test switches, connectors, relays, solenoid solid state devices, and wires of electrical/electronic circuits; determine necessary action. P-1.

Many relays are located in the fusebox and can easily be removed, replaced, or tested from this location. The fuses are also ideal spots to check for voltage drops if the circuit is hard to access. If an open is suspected in the circuit a multimeter can be used in place of the fuse for that circuit to check for the presence of current.

9. Inspect and test fusible links, circuit breakers, and fuses; determine necessary action. P-1.

Theres many parts that make up circuits here we have a common fuse box. In the fuse box one can simply remove a fuse and look at it to check if it is blown or not. Relays and circuit breakers must be tested by other means to properly diagnose them. By removing a fuse one can also easily get the amperage rating flowing in a circuit without cutting wires or disconnecting parts.

8. Diagnose the cause(s) of excessive key-off battery drain (parasitic draw); determine necessary action.. P-1.

With our multimeter hooked up to the battery we can determine if key-off parasitic draws are present. One must be careful to look up service info to find out if certain modules stay on or not to make an appropriate determination of the problem. Another way to easily check for high parasitic draw is with a test light.

7. Use wiring diagrams during the diagnosis (troubleshooting) of electrical/electronic circuit problems. P-1

In auto 170 a lot of our in class work and homework required us to know how to look up and use wiring diagrams to complete the tasks. Understanding how a circuit is wired is the first step to troubleshooting a problem. Using the information one can determine what color wire, voltage drops and so much more info pertaining to that circuit. Without this info it would be a mere guessing game for the technician.

6. Check operation of electrical circuits with fused jumper wires. P-2

In auto 170 we made fused jumper wires for testing curcuits. Above shown is a simple test to see if current flow to the battery is too high or not. These fused jumper wires are also useful for testing in line with a multi meter to help protect the costly internal fuses.

5. Check operation of electrical circuits with a test light. P-2.

In auto 170 we learned about an old testing method for electrical curcuits using a test light. Using these test lights one can check a circuit to see if current flow is present. Thought outdated and obsolete compared to a multimeter, it remains a very useful tool in the automotive field.

4. Demonstrate knowledge of the causes and effects from shorts, grounds, opens, and resistance problems in electrical/electronic circuits. P-2

In auto 170 we discussed in lab the main problems that happen to electrical circuits. Though they vary in symptom most if not all of these problems are tested with the use of a multimeter. Using a multimeter and service info diagrams to know the properties of the circuits, we completed lab sheets on finding the causes of the problem. Above shown is a frayed wire, this would cause problems such as shorts to ground possibly or even low current problems due to less conductive material.

3. Demonstrate proper use of a digital multimeter (DMM) when measuring source voltage, voltage drop (including grounds), current flow, and resistance. P-1.

In auto 170 we learned how to use our Snap On multimeters, the various settings they had and about the different accessories such as the amp clamp. Using our new found knowledge of this tool we completed several work sheets on measuring source voltage, voltage drops and current flow. Without the use of a multimeter it would be near impossible to diagnose electrical problems accurately.

.

In

2. Demonstrate knowledge of electrical/electronic series, parallel, and series-parallel circuits using principles of electricity (Ohm’s Law). P-1.

In auto 170 we had lecture about series, parallel, and series-parallel circuits. The instructor explained how the electrons flowed threw the circuit and the various other properties associated with each. After understanding a series circuits properties we went into the lab and using the snap kits above we made many different kinds of circuits. Following our in lab task sheets we used our multimeters to record various voltage readings to further our understanding of how these circuits work.

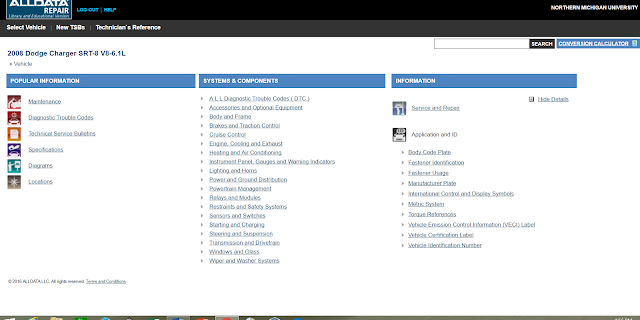

1. Research applicable vehicle and service information, vehicle service history, service precautions, and technical service bulletins. P-1

In auto 170 it was necessary to look up information on the web at times to further our understanding of how to best diagnose certain problems. Using services like ALLDATA and ProDemand, we would look up information to help us complete in class or in lab work. When given a specific problem that may be common to that vehicle, there are tsb's posted with great information to help a technician better resolve a customer concern or vehicle repair. Alternatively looking in vehicle service history can tell you whether or not the part has been replaced before or if another repair may have somthing to due with the concern.

Subscribe to:

Comments (Atom)